1.Current situation for Tie-in cutting management.

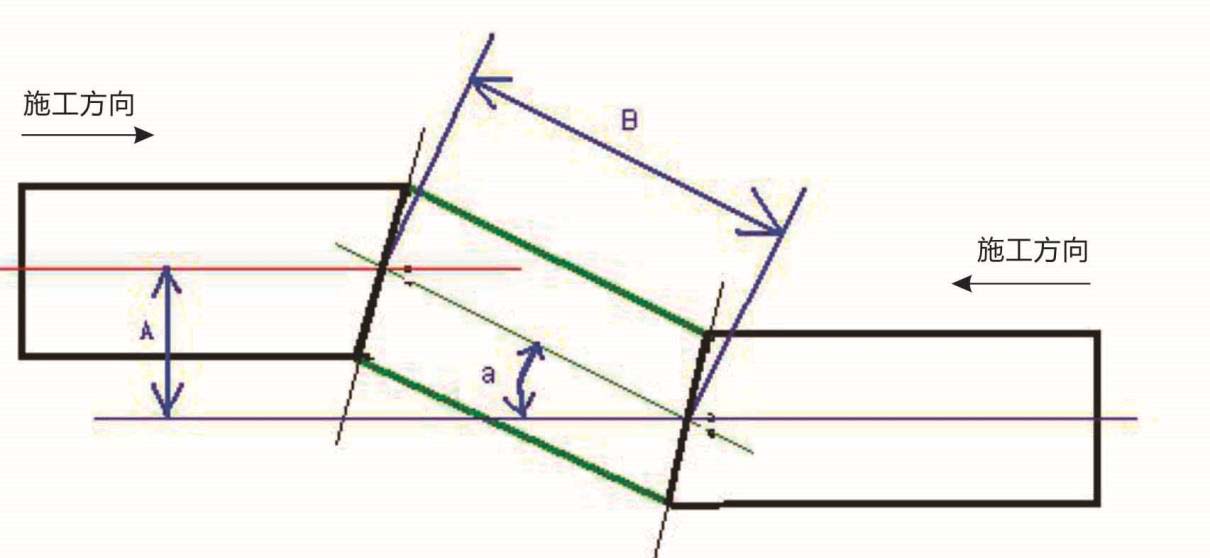

At present, for the special areas and pipes under special circumstance in the pipeline engineering, the tie-in cutting is finished by human measurement, but cutting precision will be reduced greatly when pipes across road, rivers, special hills and corners. This will make welding very difficult, no weld point or two ports overlap, especially when recovering the damaged and deformed pipes.

F1 Long-distance transportation pipeline tie-in cutting F2 Measurement

2.Current solutions for tie-in cutting

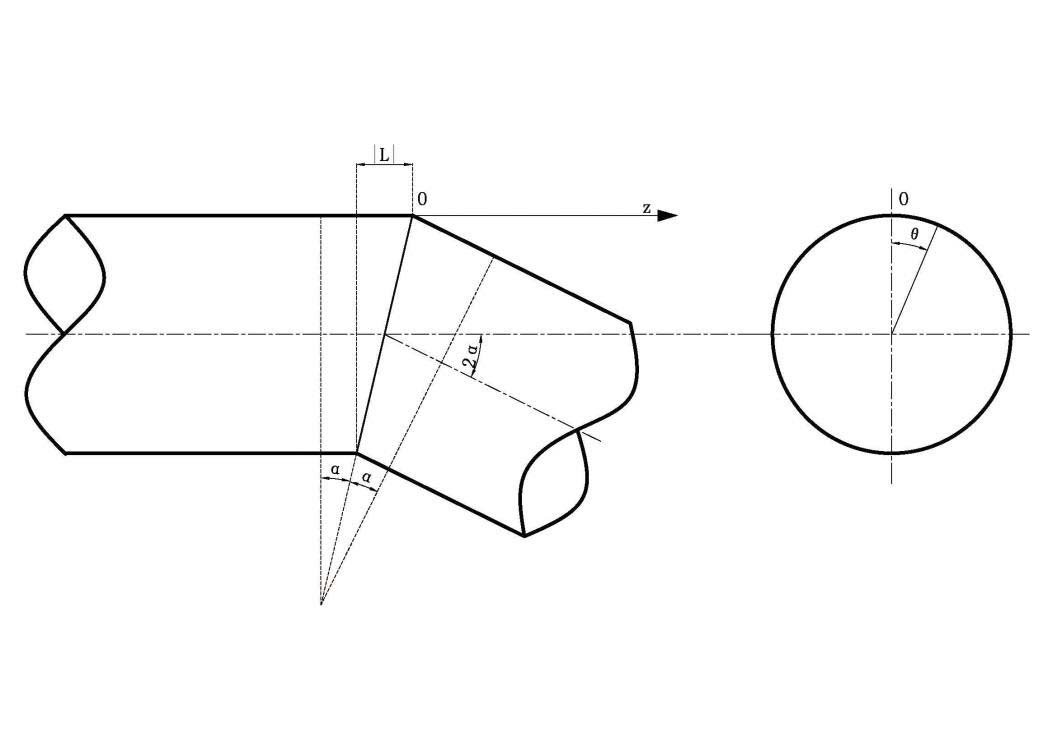

There is no good mechanical and automatic cutting method for tie-in cutting before 2010, almost all of the cutting are finished by human measurement. Depending on the formulation 1, calculating the height value of tie-in intersection line, then mark it out by drawing a line and putting a linoleum model on pipe. For diameters, please refer to F2. Usually, use a ruler to draw a X axis and Y axis. X stands for the unfolding length of outside pipe wall, Y stands for the unfolding height value of tie-in intersection line. Because the drawing is accomplished by human, generally speaking, 8 points will be chose. In order to increase accuracy, we could select 12 points or more, in theory, the more the better. After selecting the point, use a scissor to cut out the sample.

X=(D*θ*π)/360

Y=(D*tg(α/2))/2(1-cosθ)

After the sample was finished, put the linoleum model on pipes and make it fully fix on pipe surface and then use a state pencil to mark it out. The following work will be finished by workers who will use hand operated cutting torch to cut along with the line.