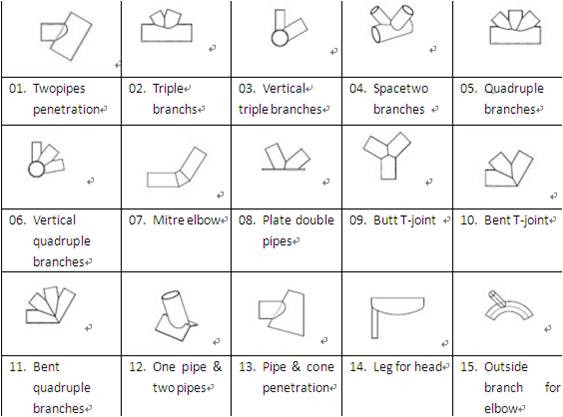

What kinds of profile models could be cut?

- Two or more penetrated pipes

Pipe and plate penetrate, pipe and cone penetrate

- Almost all the pipe interfingering line with pictures could be cut. Other models (not show in model base) could be custom Only support tube end intersection line cutting Only support tube end intersection line cutting

P1 commonly used model base

Could ThinkPipe cut pipe hole?

- Do not support pipe hole cut

P2 Only support tube end profile cut

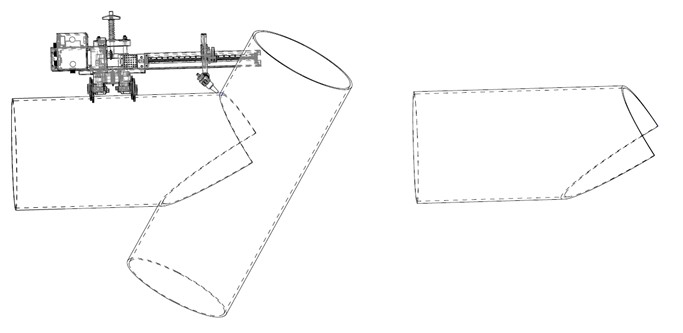

Could ThinkPipe bevel welding groove?

- TP1 series cannot bevel fixed angle welding groove, but could bevel non-fixed angle groove by adjusting the cutting torch angle.

P3 Adjust cutting torch angle

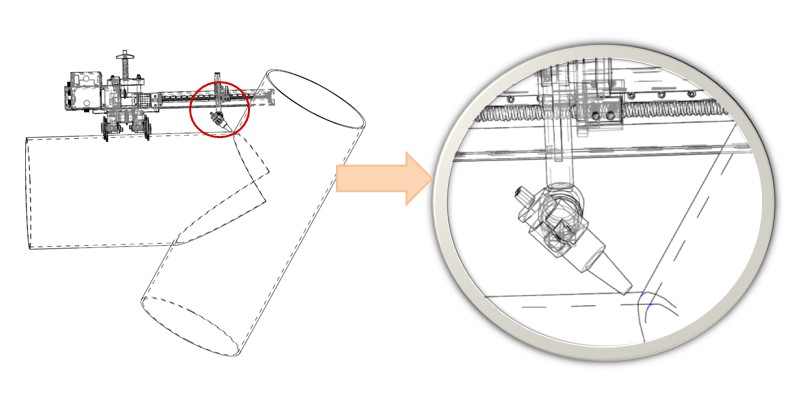

The meaning of product model Example:R40A-X means…?

R is a function code;

40 means transverse moving distance(L in picture):400mm;

A means cutting method flame

X means pipe dia range(ΦD in picture):320-3000mm。

P4 main parameter for selecting

The meaning of product model Example:R40A-X means…?

There are 3 indicator lights on the control box, how to judge whether this machine work normally or not according to them?

Light names from left to right are “running light ”,“communication light”,“power light”.

Power light is on all the time, communication light and running light twinkle and the former twinkle faster than the later.

Running Light

Communication Light

Power Light

The meaning of product model Example:R40A-X means…?

How to do maintenance according to the 3 lights?

The left running light off means something wrong with the host internal circuit board;

The middle communication light off means something wrong with the connection between sensor and host, generally, check cable connector;

The right power light off means something wrong with power, generally, check the power line.

Circuit board fault

Communication fault

Power fault

The meaning of product model Example:R40A-X means…?

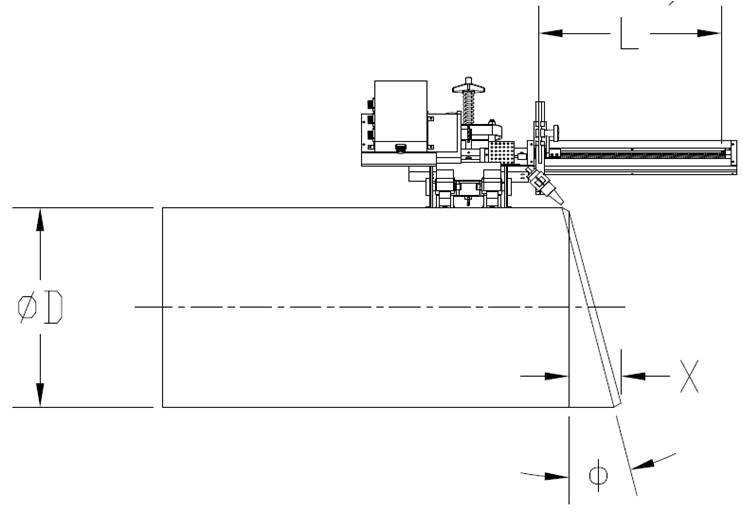

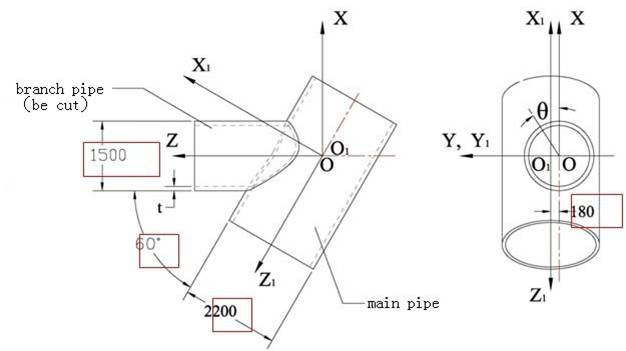

How many parameters should be input when two pipes penetrate?

A: Four

1. main pipe outer dia

2. branch pipe within dia

3. angle of two pipes

4. eccentric distance(usually eccentric value is 0).

P7 Para of two pipes penetration

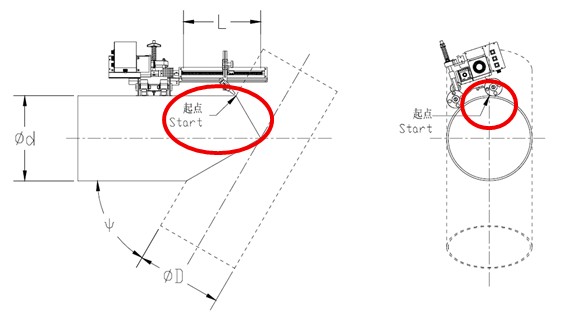

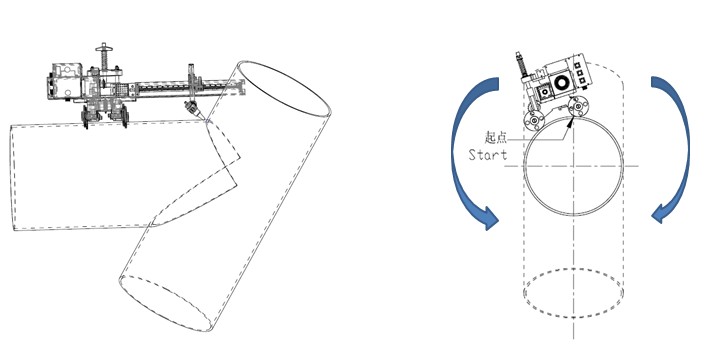

How to affirm start point to cut?

How to affirm start point to cut?

Affirm corresponding start cut points according to instruction.

Affirming start cut point is the most important thing, so should select it accurately.

P8 There is the specific definition in instruction

How to affirm cut torch’s initial place on uniaxial mechanical arm?

After inputting parameters, determine cut torch’s initial place according to the reversed left & right distance on the screen.

The initial distance is not to be very accurate. But it must meet the right & left reversed distance to avoid breaking cutting when it crushes the limit switch.

P9 Determine the cut torch’s initial location

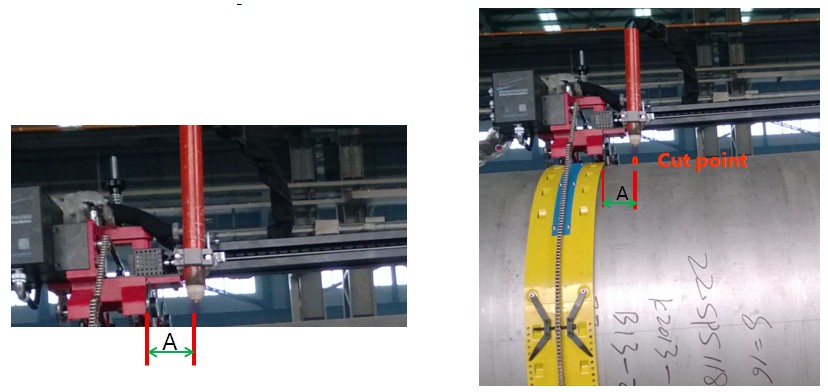

How to affirm track installation place?

Track’s installation place is determined by cut point and cut torch’s location.

The distance from track’s right side to cut point=The distance between cut torch and the inner side of right tire.

P10 Start cut point and cut torch’s location determine track installation

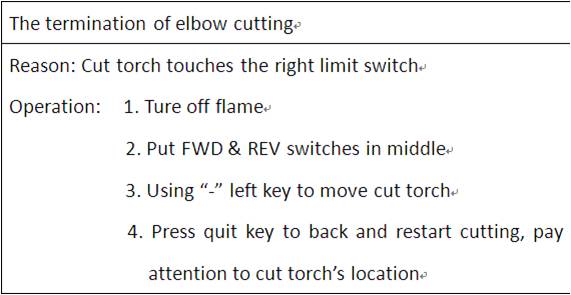

What should do when cutting torch crushes limit switch in cutting process?

To do according to the screen’s hints.

Steps:

Make sure turn off flame;

Turn off running switch

Move cutting torch according to direction keys.

Press quit key to back and restart, pay attention to cutting torch’s location.

P11 How to do after cutting torch crushes limit swithes.

Whether the cutting result is same while using forward cutting or inverse cutting?

Same

P12 No difference for forward and inverse cutting

What’s the regular pipe dia range?

All the pipes whose dia below 3m.

P13 Real photo for cutting 2200mm pipe

What’s the cutting speed?

0-800mm/min 。

How to adjust the cutting speed?

Using control panel to adjust cut speed, clockwise turns speed up and counterclockwise turns speed down.

When intersection line is very sloping and the governor’s speed is very high, the uniaxial mechanical arm’s speed beyond the highest speed, then the

cutting maybe fail because the max speed of uniaxial speed is 480mm/min. So pay attention to whether speed is in allowing range.

P14 Governor

How to judge whether cutting speed is in the allowing range?

By watching & listening. If the speed is in the allowing range, the machine works:

Watch:uniaxial mechanical arm’s motor coupling rotary intermittently;

Listen: we could hear the rhythm of cable if it’s working normally.

Could we change the cutting direction immediately when it’s cutting?

Yes. But should turn off at first and then change direction.

P16 change direction controlling

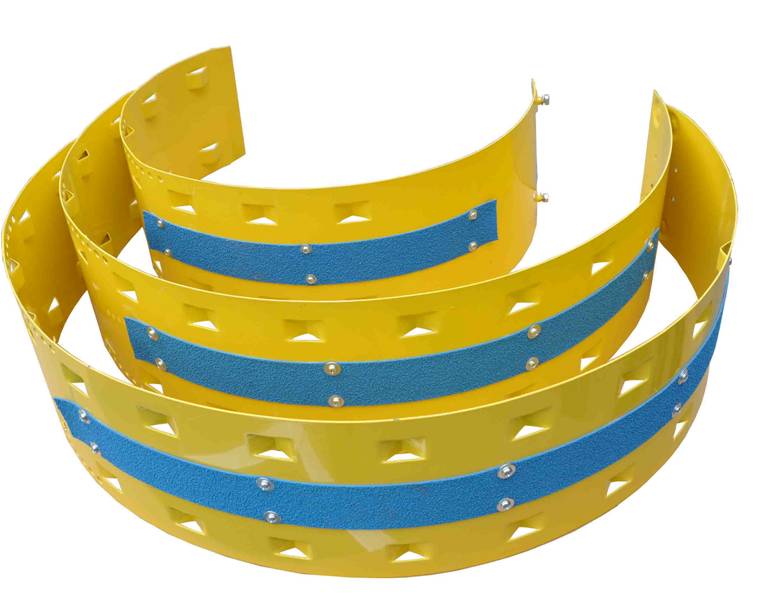

How to judge whether the tightness is suitable while installing track?

The tightness is suitable when “V groove” fully fits on steel pipes.

P17 Track “V”groove

How large space should be left around pipe for the cutting machine?

More than half meter around pipe is enough.

P18 Leave more than half meter room for machine

Why should we use forward & reverse cutting alternately while using casing?

Because control line and power line are limited, if this machine goes forward to one direction, the lines will be pulled away.

P19 Fwd & Rev cut alternately while using casing

Power supply parameter

220V/50Hz

One-way alternating current

Which two keys could be used under any interface and other keys must be used under corresponding interfaces?

“- left” &“+ right” key。

P20 “- left” &“+ right” key

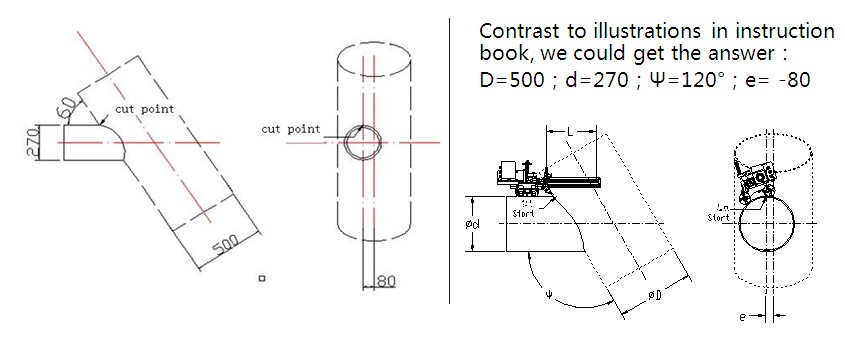

Input parameters according to the following drawings

Contrast to illustrations in instruction book, we could get the answer:

D=500;d=270;Ψ=120°;e= -80

P21 Ranging in diameter eccentric oblique penetration

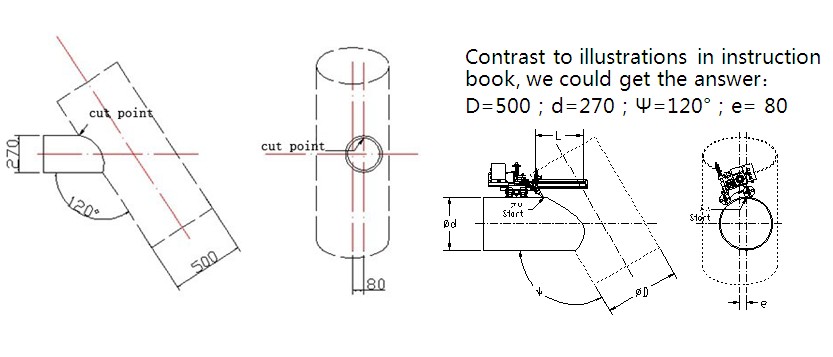

Input parameters according to the following drawings

Contrast to illustrations in instruction book, we could get the answer:

D=500;d=270;Ψ=120°;e= 80

P21 Ranging in diameter eccentric oblique penetration