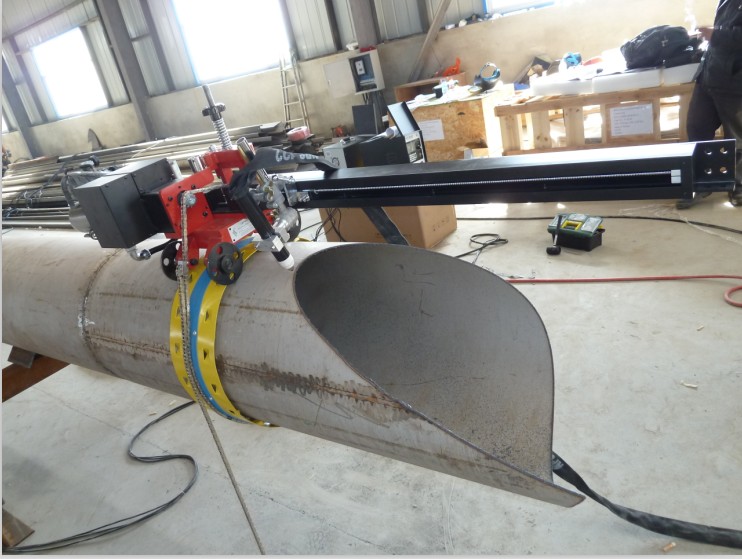

A: Yes. The cutting precision can also be guaranteed within 1mm (see Figure 1, Figure 2).

|

Figure 1 Ф1720mm*10mmPiping oblique cutting |

Figure 2 1020mm Intersecting line cutting

|

Question two: the expensive traditional pipe numerical control cutting machine can’t control the pipe that the pipe's roundness is not good, can ThinkPipe overcome it?

Answer: yes, of course .Because the device is moved along the surface of the steel pipe crawling, the out of round pipe did not affect the Welding torch’s relative position. In figure 4,the pipe is the Ф 1600mm*3mm stainless steel tube, as the diameter thickness ratio is too large, the pipe normally placed into oval, but it still doesn’t influence the cutting.

Question three: can the stainless steel or steel tube be cut?

Answer: of course it is, with the plasma arc cutting machine, we can realize cutting them, you can see figure 5, Figure 6.

|

Figure5 Ф350mm*2.5mmStainless steel pipe productione |

Figure 6 Ф600mm*2.5mmStainless steel pipe intersecting line cutting |

Question four: What is the maximum cutting diameter?

Answer: in the theory, it is 3000mm in diameter, and the actual cutting maximum diameter is 1720mm, of course, if you want to cut the 3000mm diameter pipe, we need half an hour to install ate the rail, but what all we do is worthy.

Question five: how does the ThinkPipe numerical control system against the plasma’s interference?

Answer: it’s very good. In ThinkPipe’s interior, it’s equipped with high sensitivity plasma interference module, the cable is high temperature resistant anti-static cable, and it also can be equipped with most of the domestic manufacturers of plasma cutting machine, you can save the purchase of the foreign plasma cutting machine’s cost.

Question six: are you sure that After read the instructions we will be able to use the pipe cutting machine

Answer: of course! The premise is you want to seriously seen as the year to see the same text, and we can also provide to you with PPT and video information. Of course, we do not want you are ordinary workers; we hope that you are the engineers of the company, you read the manual, and then sort out the operating instructions to the shop drawings according to your processing users. For the user, they just need to input several parameters specified by your job guidance book, click "OK", and "run" than playing smart phone simpler.

Question seven: can we visit the factory?

Answer: of course, we are very willing to have a communication with you face-to-face.

Question eight: Software upgrade need to pay?

Answer: if you have purchased the functionality, version upgrades do not require you to pay , you always have the right to enjoy the most recent version of the software. But if this is a new function, you need to pay a fee, just like in the mobile company also provides a business package the same, but the price is fair.

Question nine: How about the precision of the pipe cutting machine?

Answer: We have test report of Shanghai Quality Inspection Institute! Please believe the control system of ThinkPipe CPU calculated more accurate than manual lofting. Because CPU loft line every 0.1 seconds to take the process of cutting an accurate point location, 10 minutes cutting the equivalent of taking 6,000 (10 * 60 * 10) sampling points ,manually loft can take so many? And loft in linoleum paper can fitting the steel pipe all right? Figure six, the lofting felt paper and ThinkPipe incision were compared, we can found the large error of the manual lofting.